- Home

- About Us

-

Products

- Bosch Rexroth Star Dealer In Mumbai

- Bosch Rexroth Star Bearings Dealer

- Rexroth R 150234041

- Rexroth LM Guides

- Rexroth Ball Rail

- Rexroth-R1621

- Rexroth R 1624

- Rexroth R 1651

- Rexroth Roller Rail

- Rexroth Guideways

- Rexroth Ball Rail NRFG

- Rexroth Ball Screws

- Rexroth R 1502

- Rexroth Tychoway Bearing

- Rexroth Ball Transfer Unit

- Rexroth LM Bushing & Rexroth Linear Shaft

- Rexroth E-Line Rail

- REXROTH LINEAR BUSH R0658

- REXROTH R1027

- REXROTH -R1029

- Rexroth R 1065

- Rexroth R0670

- Rexroth R0671

- Hollow Shaft

- Rexroth Hollow Shaft

- REXROTH 0672

- Rexroth R072032500 TORQUE RESIST BUSH

- Rexroth R0673

- Rexroth TORQUE RESIST BUSH

- REXROTH R1035

- Rexroth R720 TORQUE RESIST BUSH

- REXROTH R1036

- rexroth R1038

- Rexroth R 0720 TORQUE RESIST BUSH

- Rexroth R1037

- REXROTH R0442

- REXROTH R 0600

- REXROTH R 0602

- REXROTH R 0610

- REXROTH R 0612

- REXROTH R 0632

- REXROTH R 0630

- Rexroth Linear Guide Ways

- Rexroth R 0650

- Bosch Rexroth Star Linear Bush Bearing

- Rexroth R 0740

- Rexroth R 0741

- Rexroth R 0742

- Rexroth R 1066

- bosch rexroth linear guide

- Rexroth R 1068

- Rexroth R 1065

- Rexroth R 1073

- Rexroth R 1074

- Rexroth R 1081

- Rexroth R 0668

- Rexroth R 1060

- Rexroth R 3427

- Rexroth R 3432

- Rexroth R 0732

- Rexroth R 0731

- Rexroth R 0730

- Rexroth R 0733

- Rexroth R 1701

- Rexroth R 1702

- Rexroth R 1703

- Rexroth R 1704

- Rexroth R 1706

- Rexroth R 0678

- Rexroth R 1075

- Rexroth R 1076

- Rexroth R 1077

- Rexroth R 1078

- Rexroth R 1611

- Rexroth R 1613

- Rexroth R 0696

- Rexroth R 0720

- Rexroth R 0721

- Rexroth R 0722

- Rexroth R 0723

- Rexroth R 0724

- Rexroth R 0725

- Rexroth R 0726

- Rexroth R 0727

- Segmental Linear Bushings Rexroth R0668

- Bosch Rexroth ball Screw nut FSZ E S Rexroth R1502

- Premium Quality Bosch Rexroth ball Screw nut FEM E C Rexroth R 1502

- Bosch Rexroth ball Screw nut FEM E C Rexroth R 1502

- Bosch Rexroth ball Screw nut SEM E C Rexroth R 1512

- Bosch Rexroth ball Screw nut Rexroth R 1512

- Bosch Rexroth ball Screw nut Rexroth FEM E S

- Bosch Rexroth ball Screw nut Rexroth ZEM E S

- Bosch Rexroth ball Screw nut Rexroth FED E C

- Bosch Rexroth ball Screw nut Rexroth FED E S

- Bosch Rexroth Star Bearings

- Bosch Rexroth Linear Guides

- Bosch Rexroth r 0443

- Bosch Metal Rexroth

- Bosch Rexroth r 0447

- Bosch Rexroth r 0631

- Rexroth FLS

- Rexroth FKS

- Rexroth SNH

- Rexroth SLH

- Bosch Rexroth FNN

- Bosch Rexroth FKN

- Bosch Rexroth SNN

- Bosch Rexroth SKN

- Bosch Rexroth R 165111420

- Bosch Rexroth R 165119420

- Bosch Rexroth R 165182320

- Bosch Rexroth R 165182420

- Bosch Rexroth R 165189420

- Bosch Rexroth R 165181420

- Bosch Rexroth R 165121220

- Bosch Rexroth R 165122220

- Bosch Rexroth R 165129420

- Bosch Rexroth R 165122320

- Bosch Rexroth R 165179420

- Rexroth R 1651 723 20

- Rexroth R 165141320

- Rexroth R 165152410

- Rexroth R 165152310

- Rexroth R 165311420

- Rexroth R 165381420

- Rexroth R 165322320

- Rexroth R 165372320

- Rexroth R 165331320

- Rexroth R 165332320

- Rexroth R 165341320

- Rexroth R 165342320

- Rexroth R 165352310

- Rexroth R 0602 series

- R 1863 STAR REXROTH

- Hiwin Authorised Supplier in Mumbai

- Hiwin Authorized Imported Dealer Supplier

- Hiwin

- HIWIN Linear Motors

- Hiwin Ball Screws & Nut

- Hiwin Single Axis Industrial Robot-KK-KA-KS-Series-40-50-60-86-100-130-136-170

- Hiwin Ground Ball Screws

- Hiwin LM Guide ways

- Hiwin Rolled Ball Screws

- HIWIN Kk Series-40-50-60-86-100-130-Industrial Robot

- Hiwin Linear Guide ways

- Hiwin L M Guide hgh

- Hiwin L m Guide HGW Series 15 20 25 35 45 55 65 ca-ha

- Hiwin Miniature Lm Guide MGN Series

- HIWIN LINEAR GUIDE DISTRIBUTOR MAHARASHTRA

- Hiwin Linear Guideways MGW series

- Hiwin RGW Series 25 35 45 55 CC-HC

- Hiwin Eg Series-15-20-25-30-sa-ca-hiwin egh series lm guideways

- Hiwin Egw Series-15-20-25-30-sa-ca

- Hiwin Lm Guide ways RGH Series 25 35 45 55 CA - HA

- Massage Chair Linear Actuator

- Hiwin Authroised

- Hiwin HGW Series 15 20 25 35 45 55 65-Ca-ha-cc-hc-zoc-zah

- Hiwin Egh

- Hiwin Egw 15 20 25 30 35 cc hc

- Hiwin Rgh 25 30 35 45 55 65 Ca Ha

- Hiwin ka Series-100-136-170-Multi-axis-industrial-robot

- HIWIN Ks Series-Industrial Robot-Model-KS-05-04-KS-10-05

- Hiwin Precision Ball Screw -R-40-40-S2-Dfsh

- Hiwin Precision Ball Screw -4R 25-25 -k4-DFSC

- Industrial Hiwin Ball Screw

- Hiwin Ball Screw R 20-5 T4-Fsi

- Rolled Hiwin Ball Screw

- Wing Hiwin Ball Screw

- Industrial Hiwin Ball Screw

- Industrial Ball Screw

- Hiwin Industrial Ball Screw

- Industrial Hiwin Ball Screw R 32

- Industrial Hiwin Ball Screw R 40

- Hiwin Made in India Bearing Steel Ball Screw R 50

- Hiwin Ball Screw R 50

- Hiwin Ball Screw

- HIWIN Linear Guide ways catalogue

- HIWIN Linear Guide ways QH H

- HIWIN Linear Guide ways QE H Series 15 20 25 30 35 CA HA

- Hiwin HG Series Linear Guide

- HIWIN linear guide ways ball screw Mumbai india

- HIWIN ball screw Mumbai india

- HIWIN Linear Guideways

- HIWIN Linear Guide

- HIWIN Linear Guides

- HIWIN Linear Guide ways India

- HIWIN Slide

- HIWIN QE W Series

- HIWIN Qh W Series

- HIWIN QR H Series

- HIWIN QR W Series

- Hiwin Authorized Importer Dealer Supplier

- Hiwin Authorized Dealer Mumbai India

- Hiwin Authorized Imported Dealer Supplier

- QH SERIES QHH

- Hiwin Authorized Imported Dealer MUMBAI

- Ball & Roller Bearings

- HIWIN Precision Lock Nut

- Atlanta Rack and Pinion Authorised Dealer Mumbai

- Atlanta Rack & Pinion Drive Systems

- Atlanta Integrated Rack

- Atlanta Helical Rack

- Atlanta

- Atlanta Round Rack

- Atlanta Ultra High Precision Rack UHPR Series 48 29 46 28

- Atlanta High Precision Rack HPR

- Atlanta Precision Rack PR series 38 39 33 34

- Atlanta Precision Rack PR series 38 39 33 34

- Atlanta Basic Rack BR Series 47 39 25 27 34

- Atlanta Rack

- Rack and Pinion

- Atlanta Pinion

- Rack and Pinion Drive SystemCatalog ATLANTA

- Atlanta Bevel Gear

- Atlanta racks

- Miki Pulley Authorised Dealer in Mumbai

- Servoflex Coupling

- Flexible Couplings

- ALS Couplings ALS-014-020-030-040-055-065-080

- Starflex Couplings

- SFC Model Servoflex Coupling-05-010-020-025-030-

- SFS Servoflex Coupling

- Torque Limiters Miki Pulley

- Jaw Couplings

- ALS Model Starflex Couplings

- ALS Coupling

- SFC Couplings

- SFS Coupling

- SFS Couplings

- Industrial SFS Coupling

- SS Coupling DS

- SFF Miki Pulley

- Industrial SFH Miki Pulley

- Miki Couplings

- MIKI PULLEY BRAKES

- MIKI PULLEY BRAKES 111 Model

- MIKI PULLEY Clutch 101 Model

- Belt type Stepless Speed Changer unit

- MIKI PULLEY Speed Changer Belt

- SCHMIDT COUPLINGS NSS MODEL

- SCHMIDT COUPLINGS DL MODEL

- DL MODEL COUPLING

- NSS MODEL COUPLING

- Linear Shaft Drive

- Linear Shaft Drive for Food container inspection equipment

- Linear Shaft Drive for fpd equipents

- Linear Shaft Drive for food production equipments

- SFC 020 DA2

- Miki Pulley Speed Changer

- Miki Pulley Speed Changers and Reducers

- Miki Pulley Hollow shaft Speed Changers and Reducers

- Miki Pulley Posi Lock mumbai

- ELECTROMAGNETIC CLUTCHES AND BRAKES

- Hiwin Ball Screw Authorised Stockist and Dealer

- Rexroth Bearing Dealer in Mumbai

- Rexroth-R1621

- Bosch Rexroth Ball Screw Nut

- Rexroth R

- Bosch Rexroth

- Bosch Rexroth Star

- Bosch Rexroth Star Germany R 1624

- Rexroth R 1502

- Rexroth r 1623

- Rexroth R1663

- Rexroth r1664

- Rexroth R 1661

- Rexroth R1662

- Camera Slider

- Guide ways for camera slider

- Camera Slider Guide ways in Mumbai India

- Heavy Duty High Temperature Bearings

- Linear Motion Bearings

- Quiet Linear Guideway

- High Temperature Bearings

- Linear Motion Bearing

- Quiet Linear Guideway

- Rexroth Linear Modules MKK

- NSK Dealer Nsk Lm Guides

- NSK BALL SCREW SUPPORT BEARING 55 BNR 10

- NSK BALL SCREW SUPPORT BEARING 40 BNR 10

- NSK BALL SCREW SUPPORT BEARING 50 BNR 10

- NSK BALL SCREW SUPPORT BEARING 45 BNR 10

- NSK BALL SCREW SUPPORT BEARING 75 BNR 10

- NSK BALL SCREW SUPPORT BEARING 35 BNR 10

- NSK BALL SCREW SUPPORT BEARING 100 BNR 10

- NSK BALL SCREW SUPPORT BEARING 70 BNR 10

- NSK BALL SCREW SUPPORT BEARING 95 BNR 10

- NSK BALL SCREW SUPPORT BEARING 65 BNR 10

- NSK BALL SCREW SUPPORT BEARING 60 BNR 10

- NSK BALL SCREW SUPPORT BEARING 80 BNR 10

- NSK BALL SCREW SUPPORT BEARING 85 BNR 10

- NSK BALL SCREW SUPPORT BEARING 90 BNR 10

- NSK dealer

- NSK LA Series 25 30 35 45 55 65

- NSK LH Series AN AL BN BL

- Linear Guideway

- NSK Lm Guides 15 20 25 30 35 45 55 65

- NSK PU 15 20 25 30 35 45 - PE Series

- NSK V1 Series Linear Guides

- NSK LW Series 15 20 25 30 35 45 55 65 Linear Guide

- NSK S1 Series 15 20 25 30 35 45 55 65 Linear Guide

- NSK RA -RB Series

- Dental Bearings For Handpiece

- NSK dental handpiece Bearing

- High Speed Miniature Dental Bearing

- Bearing SR 144

- Dental Hand Piece Bearing

- Dental Bearings

- NSK Spindle Bearing

- Stieber Bearings Stockist and Dealer In Mumbai

- Industrial Stieber

- ONE WAY CLUTCH BEARING

- Stieber CSK Series 12 15 17 20 25 30 35 40 P PP 2RS

- Stieber CSK Series 12 15 17 20 25 30 35 40 2RS

- Stieber CSK 12 15 17 20 25 30 35 40 P

- Stieber CSK 12 15 17 20 25 30 35 40 PP

- Stieber ASNU Series 8 12 15 17 20 25 30 35 40 45 50 60 70 80 90 100 120 150 200

- Stieber AS Series 6 8 12 15 17 20 25 30 35 40 50 60 80

- Stieber DC Series

- Stieber Clutch

- stieber One Way Clutch Bearing

- High Temperature Bearing

- McGill cam follower Bearings

- Mindman Pneumatics

- MINDMAN MP30 series

- MINDMAN MCGS series

- MINDMAN MCKA series

- Mindman MCCG series

- MINDMAN MAM SERIES

- MINDMAN MCBMI series

- MINDMAN MP41 / MP42 series

- MINDMAN MP45 series

- MINDMAN MAC series

- MINDMAN MP20 / MP25 / MP23 series

- MINDMAN MCJQ series MOUNTING BRACKET

- MINDMAN MP43 series

- MINDMAN MP1 / MP10 series

- MINDMAN MVAA series

- MINDMAN MFC series

- MINDMAN MSBS series

- MINDMAN MHPD series

- MINDMAN MDSC series

- MINDMAN MSC / MVQE / MVAS series

- MINDMAN MSLC series

- MINDMAN MPG-60 series

- MINDMAN MCMB series

- MINDMAN PG series (Pressure Gauge)

- MINDMAN MVHC Series

- UM series (Mindman Brand PU Tube)

- MINDMAN MJBV series

- MINDMAN MCQV / MCQV2 series (125~160)

- MINDMAN MCKC series

- MINDMAN MJC series

- MINDMAN MPS series

- MINDMAN MVHD series

- MINDMAN MCHJ series (Lower Height of Three-Jaw Gripper)

- MINDMAN MSAR / MSLP / MSLL / MSLD series

- MINDMAN MCRPM Series

- MINDMAN MAD series

- MINDMAN MCB SERIES

- Mindman Mvba/Mvbat Series

- MINDMAN MHBS / MHBD series

- Mindman Pneumatic Product

- Mindman Air Preparation Unit Macp Series In Mumbai

- MINDMAN MVFA series (PEDAL VALVE)

- MINDMAN MCHG Series GRIPPER

- MINDMAN MHR series

- Mindman MVSC 300 4E1 DC24

- Mindman Pneumatics Authorised dealer

- MINDMAN MPC series

- Industrial Mindman MVSC 300 4E1 DC24

- Mindman MVMC 210 3B1 8A G

- MINDMAN SC series

- MINDMAN MSR series

- MINDMAN MSLE series

- MINDMAN MEHC series

- MINDMAN MEQYC series

- MINDMAN METB series (42~80)

- MINDMAN MEAT series

- MINDMAN MCRPMS series

- MINDMAN MCRPMD series

- MINDMAN MCRPLF series

- MINDMAN MCHW series

- MINDMAN MVHS Series

- MINDMAN MVHA Series

- MINDMAN MCHY series

- MINDMAN MVHB series (Hand Lever Valve)

- MINDMAN MCHH series

- MINDMAN MCHA series(GRIPPER)

- MINDMAN MCHB series(GRIPPER)

- MINDMAN MCHC series (GRIPPER)

- MINDMAN MCKB series

- MINDMAN MRT series

- MINDMAN MCRQ series

- Mindman MCRQ-S series

- MINDMAN MCRA series

- MINDMAN MCRB series

- MINDMAN MCRJ series

- MINDMAN MCG3 series

- MINDMAN MCSS series

- MINDMAN MCDB series

- MINDMAN MCDJ series

- MINDMAN MCDA series

- Mindman MCGD series

- MINDMAN MGTK series

- Mindman MGTB series

- MINDMAN UML series (PU Tube-Coiling Tube)

- MINDMAN MACC / MACT series

- MINDMAN MAL series(AIR UNIT)

- MINDMAN MAIR series (AIR UNIT)

- MINDMAN RC* / RN* / RP* series

- MINDMAN RCI series (SENSOR SWITCH)

- MINDMAN RD* series (SENSOR SWITCH)

- MINDMAN MOUNTING BRACKET MCJQ series (LB)

- MINDMAN MCGJ series

- MINDMAN MCGD series (Standard with Magnet)

- Mindman MGTK series

- MINDMAN MGTB series

- MINDMAN MCGS series (Standard with Magnet)

- Mindman MCGJ series (Standard with Magnet)

- MINDMAN MCGB series (Standard with Magnet)

- MINDMAN MCGA series (Standard with Magnet)

- Mindman MCCN Series

- MCCN Series MINDMAN

- MINDMAN MCKMB Series (Standard with Magnet) Miniature Pneumatic Cylinders

- MINDMAN MCKQI2 series

- MINDMAN MCQN series

- MINDMAN MCBQV2 series

- MINDMAN MCBQI2 series

- MINDMAN MCJA series (40-100)

- MINDMAN MCJA series (12-32)

- MINDMAN MCJU series (Standard with Magnet)

- MINDMAN MCFA series

- MINDMAN MCFB series

- MINDMAN MCFB series (With Magnet)

- MINDMAN MCMA series (Standard with Magnet)

- MINDMAN MCMA series (With Cushion Adjustable Feature)

- MINDMAN MCMA series(MOUNTING BRACKETS)

- MINDMAN MCMA series(MOUNTING BRACKET NUTS)

- MINDMAN MCMB series (Standard with Magnet)

- MINDMAN MCMB series N TYPE (End-Plain)

- MINDMAN MCMB series E TYPE (With Pivot Type)

- MINDMAN MCKMB series (Standard with Magnet)

- MINDMAN MCCG series

- PMI Linear Rail Block Supplier in Mumbai

- Mindman Solenoid valve

- zd motor

- ZD Motor 2IK6RGN-C

- ZD Motor 3IK15RGN-C

- ZD Motor 4IK25GN-C

- ZD Motor 5IK120RGU-CF

- ZD MOTOR 4IK25RGN-C

- ZD Motor 5IK40RGN-C

- ZD Motor 3IK15GN-C

- ZD Motor 5IK40GN-C

- ZD Motor 5IK120GU-CF

- zd motor 4IK25GN C

- Zd gearbox mumbai

- ZD DC MOTOR

- zd motor 3IK15GN C

- zd motors

- zd motor 6IK180RGU-C

- ZD Motors Gear Box 78ZR5-400T1

- ZD Gear Box 60ZDF5

- ZD Motor 5IK60GU-CF

- ZD Motor 5IK60GU-SF

- ZD Motor 5IK60RGN-C

- zd motor 5IK60GN C

- ZD Motor 5IK90GU-CF

- ZD Motor 6IK140RGU-CF

- Zd motor 2IK6GN C

- ZD Motor Z2D10-24GN

- ZD Motor Z2D15-24GN

- ZD Motor Z2D30-24GN

- ZD Motor Z4D25-24GN

- ZD Motor Z4D40-24GN

- ZD MOTOR Z4D60-24GN

- ZD Motor Z5D120-24GU

- Zd Motor

- Iko Bearings in Mumbai

- Iko Japan Bearings

- Iko Needle Bearing

- iko Linear Guide ways

- Iko Spherical Plain Bearing

- IKO Cam follower Bearings

- iko cross roller bearings

- Iko LWHD Series 15-20-25-30-35-40-45-55-65

- IKO Linear Guideways Interchange

- CF 3 5 6 8 10 12 16 18 20 24 30 UU

- Cam Followers CF

- BWU Iko Bearing

- Iko BWU Bearings

- Iko BWU Precision Linear Slide Unit

- Iko BWU Precision Linear Slide Unit

- Iko BWU 25 Bearing

- Iko BWU 40 Bearings

- IKO GE

- IKO GE

- IKO GE SERIES ES 2RS

- INA Linear Guideways

- INA Axial Angular Contact Ball Bearings Series

- INA Angular Contact Ball Bearings

- INA Angular Contact Ball Bearings

- INA Angular Contact Ball Bearing

- INA Axial Angular Contact Ball Bearings Zklf..-2rs-2ap Series

- INA Axial Angular Contact Ball Bearings

- INA Axial bearings BAX series

- INA Guide Ways LFL Series 20 32 52 SF E sf

- Hiwin Linear Guideways

- INA Linear Guide Ways

- Rexroth linear guideways

- INA Rwu Series 25 35 45 55 65 D E L H HL

- INA KWE 15 20 25 30 35 H

- INA KWVE 15 20 25 30 W WL B L H HL E N NL S SL

- INA KWSE 20 25 30 35 45 L H HL

- INA KWEM 5 7 9 12 15 L C W WL

- INA Track Roller Guide Way

- INA Track Roller Guide Way

- INA LFCL 25 42 86

- INA LFL 20 32 52 sf

- INA LFL 52 E sf

- INA LFKL 20 25 32 52 E SF EE SF

- INA LFDL 32 52 B SF

- INA Ball Screw Support Bearing

- INA Ball Screw Bearing

- INA Ball Screw Bearing ZKLF 2RS 2Z 2AP 2RS-pe

- INA ZKLF 2RS 2AP

- INA ZKLF 1762 2RS 2AP

- Rust Proof Heavy Duty INA Ball and Roller Bearing

- INA Ball and Roller Bearing

- Ball Screw Bearing

- Axial angular contact ball bearings

- INA Bearing

- INA Linear Guideways

- INA ZKLN 2rs 2z 2ap 2rs-pe

- INA ROLLER BEARING RUS 19069

- INA ROLLER BEARING RUS 19105

- INA ROLLER BEARING RUS 26086

- INA ROLLER BEARING RUS 26102

- INA ROLLER BEARING RUS 26126

- INA ROLLER BEARING RUS 38134

- INA ROLLER BEARING RUS 38206

- INA ROLLER BEARING RUS 65210

- INA ROLLER BEARING RUS 85280

- INA Axial Bearings 7602 Series

- INA Axial angular 7602..-2RS Series

- INA Contact Ball Bearings

- INA Axial Angular Contact Ball Bearings

- INA Angular contact ball bearing ZKLFA-2Z SERIES

- INA Angular contact ball bearing ZKLFA-2RS SERIES

- INA DKLFA-2RS SERIES

- THK Ball Screws

- Lm Guide ways

- Hiwin Linear Guideways

- Linear Guideways

- Nsk Guide Ways Alternate Exchange Interchange

- Iko Lm Guide Alternate Exchange Interchange

- Star Rexroth Lm Guide Exchange

- INA Linear Guide ways Alternate Exchange

- Hiwin Linear Guideways CG Series

- Hiwin Linear Guideways E2 Series Self Lubricant

- Hiwin Linear Guideways EG Series

- Hiwin Linear Guideways HG Series

- Hiwin Linear Guideways MG Series

- Hiwin Linear Guideways QE Series

- Hiwin Linear Guideways QH Series

- Hiwin Linear Guideways QR Series

- Hiwin Linear Guideways QW Series

- Hiwin Linear Guideways RG Series

- Hiwin Linear Guideways WE Series

- Hiwin Linear Guide Ways For Hesheng Machinery

- Lm Bush

- Lm Guide

- Ball Screws

- Linear Ball Screws

- Hiwin Rolled Ball Screws

- Diamond Cutting Ball Screws

- Ground Ball Screw FSV DFSI DFSH FSW FDV FDW DFSC FDI FSI 16-4 T3 T4 T6

- Hiwin Ballscrews

- Ball Screw Cool Type II Series

- BAll Screw Cool Type I Series

- Ball Screw Dust Proof Options

- Hiwin Ball Srew Heavy Load Series

- Hiwin Miniature Ground Ballscrews

- Hiwin Precision Ground Ballscrew

- Hiwin Rolled Ball screw

- Hiwin Roller Screw

- Hiwin Ball Screw Super S Series

- Hiwin Ball Screw Super T Series

- Hiwin Ball Screw R1 Series Rotating Nut

- Actuators

- Cross Roller Slides

- Cross Roller Bearing Slides

- NB CROSS ROLLER GUIDE

- THK CROSS ROLLER GUIDE WAYS

- IKO CRW SERIES

- SCHNEEBERGER CROSS ROLLER SLIDE

- THK VR SERIES VR 1-2-3-4-6-9-12 CROSS ROLLER SLIDE

- NB SV SERIES SV 1-3- 4- 6- 9- 12- CROSS ROLLER SLIDE

- NB JAPAN SVW SERIES CROSS ROLLER SLIDE

- IKO CRWM SERIES

- NB CROSS ROLLER GUIDE SVT SERIES

- THK VRT Series Slide Table

- Thk VRU series

- Schneeberger nk series

- Schneeberger ND series

- Rexroth Hydraulic Valve

- Directional Control Valve Rexroth R900561274

- Flow Control Valve Rexroth R900205510

- Rexroth Hydraulic Directional Control Valve

- Rexroth Hydraulic Flow Control Valve

- Rexroth Pressure Control / Pressure Relief valves

- Rexroth Hydraulic Check / Non - Return Valve

- Rexroth Hydraulic Prefill Valves

- Rexroth Compact Hydraulic Valve

- Rexroth Pressure Reducing Valve R901205987

- Industrial Hand Lever Valves

- Festo Valves

- HALDER

- HALDER SPRING PLUNGER

- HALDER INDEX PLUNGER/ INDEX BOLTS

- HALDER LOCKING ELEMET

- HALDER LIFTING PINS

- HALDER BALL LOCK PINS

- HALDER MOUNTING PADS

- HALDER LOCATING AND SEATING ELEMENTS

- HALDER PUSH PLUNGERS

- HALDER SELF ALIGNING PADS

- Halder Ball Casters

- Halder Positioning Sensors

- Halder Expander Sealing Plugs

- THK Linear Guide Ways

- Industrial THK Ball Spline

- THK LM Guide HSR 15 20 25 30 35 45 55 65 A R

- THK NS 2525 A BALL SCREW

- THK LR-Z SERIES

- THK BNSA BNS NSA NS series Ball Screw Spline

- THK KR 2602 A 0060 P0 10A0

- THK LM GUIDE ACTUATOR KR3006HA

- THK BNS

- THK CROSS ROLLER LR SERIES

- THK NS 0812 1015 1616 2020 2525 3232 4040 5050 A

- thk SPLINE LBST30UU 580L

- THK HR SERIES

- THK HR SERIES 918 1123 1530 2042 2555 3065 3575 4085 50105 60125 M

- THK Ball Spline

- Thk Bearing Linear Guide Ways Ball Screw Mumbai India

- THK KR Series Linear Slide Actuator

- Thk HSR Series

- Thk LMK

- THK Linear Guide Ways

- CNC Component THK Linear Guide Ways

- THK HRW SERIES 12 14 17 21 27 35 50 60

- THK STROKE BUSH ST STB STI SERIES

- THK ST 8 10 12 16 20 25 30 35 40 45 50 55 60 65 70 75 80 100 UU B

- THK Ball Spline LBS 10 15 20 25 30 40 50

- THK Ball Spline LT 5 10 15 20 25 30 40 50 60 80 100

- THK Ball Spline LBS30UU And 280L

- Skf Bearing

- SKF linear guide LLTHC U

- SKF Linear guide LLTHC A

- SKF linear guide LLTHC SU

- SKF Linear Guide LLTHC LA

- SKF Tandem linear bearing units LTCD

- SKF Quadro linear bearing units LQCD

- SKF Linear Bearing Units LUNE

- SKF Linear ball bearings LBBR

- SKF Linear bearing units LUCT.BH

- SKF linear guide LLTHR D4

- SKF linear guide LLTHC LR

- SKF linear guide LLTHC R

- SKF BS2 bearing

- SKF Bearing

- SKF Grease

- SKF SYSTEM 24 LAGD 125 Single Point Automatic Lubricators

- SKF Linear ball bearings LBCR

- SKF Linear ball bearings LBCD

- SKF Linear ball bearings LBCT

- SKF Linear ball bearings LBHT

- SKF Linear ball bearings LBCF

- SKF Linear plain bearings LPBR

- SKF Linear plain bearings LPBR

- SKF Linear plain bearings LPAT

- SKF Linear bearing units LUHR

- SKF Linear bearing units LUJR

- SKF Tandem linear bearing units LTBR

- SKF Duo linear bearing units LTDR

- SKF Quadro linear bearing units LQBR

- SKF Linear bearing units LUCR

- SKF Linear bearing units LUCD

- SKF Linear bearing units LUCS

- SKF Linear bearing units LUCE

- SKF Linear bearing units LUCT

- SKF Linear bearing units LUCF

- SKF Linear bearing units LUND

- SKF Linear bearing units LUNF

- SKF FLANGED LINEAR BEARING UNITS LVCR

- SKF Tandem linear bearing units LTCF

- SKF Quadro linear bearing units LQCR

- SKF Quadro linear bearing units LQCF

- SKF shaft supports LRCB

- SKF shaft supports LRCC

- Tsubaki

- TSUBAKI One Way Clutch Bearing

- TSUBAKI Clutch

- Cam clutch bearing

- Cam clutch tsubaki

- TSUBAKI TSS Series

- TSUBAKI TSS Series Cam Clutch

- TSUBAKI TFS Series Cam Clutch

- TSUBAKI TFS Series

- TSUBAKI BB SERIES CAM CLUTCH

- INDUSTRIAL TSUBAKI

- Industrial Tsubaki

- Tsubaki Cam Clutch BB TSS TFS BR Series tsubaki catalogue

- Tsubaki catalogue

- KLUBER

- Zimmer

- Servo Motor Couplings & Motion Control Zero Max

- TPI BEARING

- TPI Ball Screw Support Bearings BS 17 tac 47

- TPI Ceramic Bearings 7006

- TPI Ceramic Bearings 7003

- TPI Precision Bearings 7207 C

- TPI Precision Bearings 7200 C

- TPI Precision Bearings 7011 C

- TPI Precision Bearings 7008 C

- TPI Precision Bearings 7210 C

- TPI Precision Bearings 7004 C

- TPI Ball Screw Support Bearings BS 25 tac 62

- TPI Precision Bearings 7003 C

- TPI Precision Bearings 7005 C

- TPI Precision Bearings 7014 C

- TPI Precision Bearings 7206 C

- TPI Precision Bearings 7010 C

- TPI Precision Bearings 7012 C

- TPI Precision Bearings 7017 C

- TPI Ceramic Bearings 7004

- TPI Precision Bearings 7209 C

- TPI Precision Bearings 7001 C

- TPI Bearings NN 3022 K P4

- TPI Precision Bearings 7208 C

- Industrial TPI Precision Bearings 7006 C

- TPI Ceramic Bearings 7005

- TPI Ceramic Bearings 7007

- TPI Precision Bearings 7002 C

- TPI Precision Bearings 7205 C

- TPI Precision Bearings 7204 C

- TPI Precision Bearings 7020 C

- TPI Precision Bearings 7000 A

- TPI Precision Bearings 7201 C

- TPI Precision Bearings 7007 C

- TPI Precision Bearings 7013 C

- TPI Precision Bearings 7018 C

- TPI Precision Bearings 7202 C

- TPI Precision Bearings 7015 C

- TPI Precision Bearings 7009 C

- TPI Precision Bearings 7016 C

- TPI Ball Screw Support Bearings BS 35 tac 72

- TPI Ball Screw Support Bearings BS 40 tac 72

- TPI Precision Bearings 7006 C

- TPI Ball Screw Support Bearings BS 30 tac 62

- TPI Ball Screw Support Bearings BS 20 tac 47

- NSK BEARING 25 TAC 62 B SUC10PN7B

- TPI PRECISION BEARING

- TPI ANGULAR CONTACT BEARING

- NSK BEARING 17 TAC 47 B

- BALL SCREW SUPPORT BEARING

- NSK 17TAC47 B SUC10PN7B

- NSK BEARING 45 TAC 75 B SUC 10 PN 7B

- NSK BEARING 35 TAC 72 B SUC 10 PN 7B

- NSK 40TAC72 B SUC 10 PN 7B

- NSK BALL SCREW BEARING 30 TAC 62 B SUC 10 PN 7B

- NSK BEARING 15 TAC 47 B

- TPI Precision Bearings 7203 C

- TPI Bearings NN 3018 K P4

- TPI Bearings NN 3020 K P4

- Master & Mechanical Valve

- Mindman Air Units

- Pressure reducing valves Model: MAR401

- Air Filter Model: MAF403

- Pressure Reducing Valves Model: MAR500

- Pressure Reducing Valves Model: MAR402

- Precision Regulator Model: MAIR200

- Pressure Reducing Valves Model: MAR301

- Air units

- Micromist Filter

- Mist Filter

- AIR unit

- Air filter

- Air units

- Auto Drain Valves

- Auto Drain Valves Model: FMRF300

- Air units (Auto-drainer)

- Air units (Drain Trap)

- Auto Drainer

- Digital Condensation Removal Timer

- Air units (F.R.L.Unit) MACP200

- Air units (F.R.L.Unit) Stainless steel type

- Air units (F.R.L.Unit) Stainless Steel Type Model: MACT410

- F.R.L.Unit

- Air units (F.R.Unit)

- Air units (F.R.Unit) Model: MAFR500

- Air units (F.R.Unit) Stainless steel type

- Air units (F.R.Unit) Stainless steel type Model: MAFR410

- F.R.Unit Model: MAFR403

- F.R.Unit Model: MAFR401+MP41

- F.R.Unit Model: MAFR302+MP41

- F.R.Unit Model: MAFR200L

- Air units (Filter) Model: MAF200

- Air units (Filter) Model: MAF901

- Air units (Filter)

- Air units (Filter) Model: MAF401

- Air units (Filter) Stainless Steel Type

- Filter Model: MAF200L

- Filter for Turbine Type Model: MWA-300

- Filter for Turbine Type Model: MWC

- Hand-held Regulator Model: MAR300LK

- High Efficiency Compressed Air Filter

- Air units (L.Unit) Model: MAL200

- Air units (L.Unit) Model: MAL900

- Air units (L.Unit) Model: MAL500

- Air units (L.Unit) Model: MAL401

- Air units (L.Unit) Stainless Steel Type Model: MAL310

- Lubricator Model: MAL403

- Precision Regulator Model: MAIR100

- Pressure Reducing Valves Model: MAR302

- Air units (R.Unit) Pilot operated

- Mindman Pressure Switch

- Pneumatic Pressure Switch Model: MP20/MP25

- Pressure gauge

- Pneumatic Pressure Switch Model: MP1

- Pneumatic Pressure Switch Model: MPS

- Pneumatic Pressure Switch Model: MP41

- Pneumatic Pressure Switch Model: MP25

- Pneumatic Pressure Switch Model: MP10

- Pneumatic Pressure Switch Model: MP42

- Pneumatic Pressure Switch Model: MP30

- Pressure Gauge Model: MP23

- Mindman Compressed Air Dryer

- Mindman Standard Cylinders

- Mindman Compact Cylinders

- Mindman Mini Cylinders

- Flat Cylinders Model: MCMOB

- ISO-6432 Miniature Cylinders

- Miniature Cylinders Model: MCMB

- Miniature Cylinders Model: MCMA

- Miniature Cylinders Model: MCMBR

- Oval Micro Cylinders Model: MCMOC

- Pen Cylinders Model: MCMJ

- Pen Cylinders Model: MCMJ1

- Pen Cylinders Model: MCMJP

- Pen cylinders Model: MCMJPB

- Pen Cylinders Model: MCMJPS

- Rod Locking Cylinders

- Mindman Round Cylinders

- Mindman Guide Cylinders

- Mindman Table

- Mindman Rotary Actuator

- Mindman Clamp Cylinders

- Mindman Grippers

- 180 Angular Gripper Cam Style Model: MCHY

- 180 Angular Grippers Rack & Pinion Style Model: MCHW

- Four Jaw Grippers

- Grippers Model: MCHA

- Lower Height Parallel Grippers Model: MCHQ

- Parallel Grippers Model: MCHB

- Parallel Grippers Model: MCHH

- Slim Parallel Grippers Model: MCHU

- Wide Type Parallel Grippers Model: MCHX

- Lower Height of Three Jaw Grippers Model: MCHG

- Lower Height of Three Jaw Grippers Model: MCHG2

- Three Jaw Grippers Model: MCHG2L

- Three Jaw Grippers Model: MCHGH

- Mindman Auxiliary Equipments

- Pneumatic Presses Model: MF

- Booster Regulator Model: MVBA-2100

- Check valve Model: MJBV

- Coupler Model: MS

- Exhaust Cleaner Model: MEF300

- Female Rod Ends Model: PHS

- Floating Connector Model: MFC

- Flow Control Valve Model: MSC

- Hydraulic Speed Controllers Model: MHR

- Jet Cooler Model: MJC

- No Contact Transfer Model: MHPSC

- Pilot Check Valves Model: MPC

- PU Tube Model: UM / TPU

- Quick Exhaust Valve Model: MVQE

- Sensor Switch Model: RCA

- Sensor Switch Model: RCB

- Sensor Switch Model: RCD

- Shock Absorbers Model: MAC / MAD

- Shock Absorbers Accessories Model: SC

- Shuttle Valve Model: MVAS

- Brass Silencer Model: MSL

- Plastic Silencer Model: MSR

- Plastic Silencer Model: MSLE

- Silencer Throttle Valve Model: MSLS

- Silencer Throttle Valve Model: MSLC

- Mindman Solenoid Valve

- 5/2 SINGLE SOLENOID VALVE 22 MM BODY WIDTH MVSC220-4E1-DC24

- Solenoid Valve MVSC Series Model: MVSC-300

- Solenoid Valve MVSG Series Model: MVSG-180

- Solenoid valve (Direct operated type) MVDC Series

- Multi Connector System Model: MVB

- Solenoid Valve (Direct operated type) MVDY Series

- Solenoid Valve MVSA Series Model: MVSA-150

- Solenoid Valve MVSA Series Model: MVSA-156

- Solenoid Valve MVSA Series Model: MVSA-180

- Solenoid Valve MVSA Series Model: MVSA-260

- Solenoid Valve MVSA Series Model: MVSA-300

- Solenoid Valve MVSB Series Model: MVSB-180

- Solenoid Valve MVSB Series Model: MVSB-188

- Solenoid Valve MVSC Series Model: MVSC-180

- Solenoid Valve MVSC Series Model: MVSC-260

- Solenoid Valve MVSC Series Model: MVSC-460

- Solenoid Valve MVSC Series Model: MVSD-180

- Solenoid Valve MVSE Series Model: MVSE-260

- Solenoid Valve MVSE Series Model: MVSE-300

- Solenoid Valve MVSE Series Model: MVSE-500

- Solenoid Valve MVSE Series Model: MVSE-510

- Solenoid Valve MVSE Series Model: MVSE-600

- Solenoid Valve MVSF Series Model: MVSF-100

- ISO-1 Solenoid Valve MVSI Series Model: MVSI-260

- ISO-1 Solenoid Valve MVSI Series Model: MVSI-450

- ISO-3 Solenoid Valve MVSI Series Model: MVSI-510

- NAMUR Solenoid Valve MVSN Series Model: MVSN-300

- Solenoid Valve MVSY Series Model: MVSY-156

- Solenoid Valve MVSY Series Model: MVSY-100

- Solenoid Valve MVSY Series Model: MVSY-188

- Solenoid Valve MVSZ Series Model: MVSZ-100

- 5/2 SINGLE SOLENOID VALVE 22 MM BODY WIDTH MVSC220-4E1-AC220

- ACT Mechanical Valve

- Mindman Solenoid Valve (2 Way)

- Solenoid Valve MBS Series Model: MBS

- Solenoid Valve 2 Way MC* series Model: MCT

- Solenoid Valve 2 Way MC* Series Model: MCS

- 2/2 Way small size N.C. Diaphragm Series Solenoid Valve Model: MED

- Solenoid Valve ME* series Model: MEP

- 2/2 Way N.C.Small Type Piston Series Solenoid Valve Model: MGA

- Solenoid Valve 2 Way MG* Series Model: MGS

- Solenoid Valve 2 Way MG* Series Model: MGD

- 2/2, 3/2 Way Plunger Series Actuator Valve Model: MJ

- 2/2 Way Diaphragm Series n.c. Solenoid Valve Model: MPK

- Solenoid Valve 2 Way MP* Series Model: MPD

- 2/2 Way N.O. Plunger Series Solenoid Valve Model: MRB

- Solenoid Valve 2 Way MR* Series Model: MRC

- 3Way 2 Position Solenoid Valve MU* Series Model: MUA

- Solenoid Valve MU* Series Model: MUD

- Solenoid Valve MU* Series Model: MUDC

- Solenoid Valve MU* Series Model: MSUS

- Solenoid Valve MU* Series Model: MUAO

- Solenoid Valve MU* Series Model: MUW-NO

- Solenoid Valve MU* Series Model: MUW

- Solenoid Valve MU* Series Model: MUW-F

- Solenoid Valve MW* Series Model: MW

- 2/2 Way N.C. Y Type Piston Series Solenoid Valve Model: MY

- 2/2 Way N.C. Plunger Series Direct Acting Solenoid Valve Model: MZ

- Mindman AIR REGULATOR

- Mindman Single Solenoid

- 5/2 SINGLE SOLENOID MVSC-220-4E1- DC24

- 5/2 SINGLE SOLENOID MVSC-260-4E1-DC24

- 3/2 SINGLE SOLENOID MVSC-220-3E1-NC-DC24

- 5/2 SINGLE SOLENOID MVSC-220-4E1-AC220

- 5/2 SINGLE SOLENOID MVSC-220-4E2-DC24

- 5/3 CENTRE OFF SINGLE SOLENOID MVSC-220-4E2C- DC24

- 5/2 SINGLE SOLENOID MVSC-260-4E1-AC220

- 5/2 SINGLE SOLENOID MVSC-260-4E2-DC24

- 5/2 SINGLE SOLENOID MVSC-300-4E1-DC24

- 5/2 SINGLE SOLENOID MVSC-300-4E1-AC220

- 5/2 SINGLE SOLENOID MVSC-300-4E2-DC24

- 5/2 SINGLE SOLENOID MVSC-460-4E1-DC24

- 5/2 SINGLE SOLENOID MVSC-460-4E1-AC220

- 5/2 DOUBLE SOLENOID MVSC-460-4E2-DC24

- 5/2 SINGLE SOLENOID MVSD-180-4E1-DC24

- 5/2 SINGLE SOLENOID MVSD-180-4E1-AC220

- 5/2 SINGLE SOLENOID MVSD-180-4E2-DC24

- Angular Contact Bearing

- Needle Roller Bearings

- Shafts & Shaft Collars

- Timing belts

- EZO Bearing

- KHS BEARINGS

- KHS DAWN CUP NEEDLE ROLLER BEARING

- DRAWN CUP NEEDLE ROLLER BEARING

- MACHINED TYPE NEEDLE ROLLER BEARING

- KHS THRUST NEEDLE ROLLER BEARING

- KHS DRAWN CUP NEEDLE ROLLER CLUTCHES

- KHS Stud And Yoke Type Track Roller Bearings

- KHS Rod End Bearings

- KHS Linear Motion Bearings

- KHS Linear Motion Shaft With Support

- KHS NEEDLE ROLLER AND RAGE ASSEMBLIES

- KHS TRACK ROLLER BEARINGS

- KHS RADIAL SPHERICAL PLAIN BEARINGS

- KHS PERMAGLIDE DRY BLUSH

- KHS ONE WAY CLUTCH

- KHS FLAT ROLLER CAGES

- KHS DUAL SHAFT GUIDES

- Hi More Robot

- HI MORE INJECTION MOULDING ROBOT THS 1300 1500 1800W SERIES

- HI MORE INJECTION MOULDING ROBOT UNB 1500TW SERIES

- HI MORE INJECTION MOULDING ROBOT HX 100-300 SERIES

- HI MORE INJECTION MOULDING ROBOT THS 850 950 SERIS

- HI MORE INJECTION MOULDING ROBOT ST Series

- HI MORE INJECTION MOULDING ROBOT THS 850 950 1100W SERIES

- HI MORE INJECTION MOULDING ROBOT HX 80 100 200 SERIES

- HI MORE INJECTION MOULDING ROBOT UTS 650 1100 SERIES

- HI MORE INJECTION MOULDING ROBOT HA 950SW SERIES

- HI MORE INJECTION MOULDING ROBOT UX F III 250 550 SERIES

- HI MORE INJECTION MOULDING ROBOT ZH SERIES

- HI MORE INJECTION MOULDING ROBOT UZSII 800 1000W SERIES

- HI MORE INJECTION MOULDING ROBOT UXV 60 150 SERIES

- HI MORE INJECTION MOULDING ROBOT UX30 150 SERIES

- HI MORE INJECTION MOULDING ROBOT HA 1100SW SERIES

- YYC Rack and Pinion Distributor and supplier in In

- Linear Bearings Block

- THK Lm Block Exchange Interchange

- SKF Shaft blocks LSNS

- SKF Tandem shaft blocks LEAS

- HIWIN LM Block LM Guide Alternate

- Bosch Rexroth Runner Block R1651

- SKF Tandem shaft blocks LEBS

- bosch rexroth linear bearings Block R 1665

- Rexroth R-1651 Runner Block Bearing

- Rexroth Runner Block R 1693

- KHS PILLOW BLOCK BEARINGS

- Rexroth_bosch_runner_block R_1666

- R 165139420 rexroth runner block

- bosch_rexroth_star_Linear_block_R_1653

- R 165132320 rexroth runner block

- R 165142320 rexroth runner block

- Rexroth Runner Block

- Rexroth SKS Series Runner Block

- Rexroth Ball Runner Block FNS Series

- Rexroth SLS Series Runner Block

- Rexroth ball runner block SNS series

- Hiwin Lm Block Rgh 45 H

- Hiwin Lm Block Hgh 45 H

- Industrial Bearing Block

- Bearing Block

- SKF Shaft blocks LSCS

- Industrial Cylinder Series

- End lock Cylinders

- Rodless Cylinders Model: MCRPL

- MINDMAN REPAIR KITS MCMI MINIATURE CYLINDER

- Rodless Cylinder with Linear Guide Model: MCRPLK

- MINDMAN MCJA series (40-100) MAGNET CYLINDER

- ISO-VDMA Standard Cylinders

- Magnetically Coupled Rodless Cylinder Model: MCRPM

- ISO-VDMA Standard Cylinders Model: MCQV2

- MINDMAN MCJI SERIES COMPACT CYLINDER(FEMALE)

- Stopper Cylinder Model: MSAR

- ISO-VDMA Standard profile cylinders

- MINDMAN MCGI SERIES COMPACT CYLINDER NON ROTATING

- Stopper Cylinder Model: MSBD

- Mindman Mcji Series Compact Cylinder Male

- Rod Locking Cylinders Model: MCBQV

- MINDMAN MCJQ series (12~32) (COMPACT CYLINDER)

- Stopper Cylinder Model: MSL

- Rod Locking Cylinders Model: MCBQI2

- Stopper Cylinder Model: MSBR

- Standard Cylinders Model: MCQA

- MINDMAN MCJQ series(40-100) (COMPACT CYLINDER)

- Standard Cylinders Model: MCQN

- MINDMAN MSBD / MSBR / MSBS series (STOPPER CYLINDER)

- Stopper Cylinder Model: MSBS

- MINDMAN MSAR / MSLP / MSLL / MSLD series (STOPPER CYLINDER)

- Compact Cylinders Model: MCJQ

- Compact Cylinders ( Back to back type) Model: MCJT-4

- MINDMAN REPAIR KITS MCJI COMPACT CYLINDER

- MINDMAN REPAIR KITS MCQI2 CYLINDER

- Compact Cylinders Model: MCJS

- MINDMAN MCQV2 series (Cylinders ISO-6431 & VDMA-24562)

- Compact Cylinders (Multiple position) Model: MCJT-3

- Compact Cylinders Model: MCJQ2

- MINDMAN MCQI2 SERIES(SINGLE SIDED CYLINDER)

- Compact Cylinders Model: MCJK

- MINDMAN MCQI2 SERIES(DOUBLE SIDED CYLINDER)

- Standard Cylinders Air/oil converter

- Compact Cylinders Model: MCJT

- Mindman Series MCHY Double Acting Gripper Cylinder

- MINDMAN MCCG Series Pneumatic Round Cylinder

- MCJA Series (12-32) Mindman Compact Cylinder

- Halder Screw

- Mindman Product

- Bosch Rexroth Star Dealer In Mumbai

- Brands

- Contact Us

Stone Polising Machinery Components

MOQ : 1 Piece

Stone Polising Machinery Components Specification

- Weight

- Lightweight Design

- Cutting Speed

- Optimized for Efficient Polishing

- Spindle Speed

- Variable

- Hardness

- High-Grade

- Thread Type

- Standard

- Load Capacity

- Standard Industrial Capacity

- Machine Type

- Polishing Machine Components

- Shape

- Cylindrical and Linear

- Coating

- Anti-Rust Coating

- Size

- Customized

- Accuracy

- High Precision

- Method

- Mechanical

- Type

- Machinery Components

- Material

- Stainless Steel

- CNC

- Yes

- Tolerance

- Strict

- Surface

- Smooth and Durable

- Use

- Industrial

- Application

- Stone Polishing Machinery

- Usage & Applications

- Stone Polishing and Processing

About Stone Polising Machinery Components

Experience unbeatable price and instant savings on our first-string Stone Polishing Machinery Components, meticulously engineered for the enlightened industrial user. Each lightweight, high-grade stainless steel component boasts strict tolerance, high precision, and a smooth, durable surface. With variable spindle speed and optimized cutting efficiency, your polishing processes achieve invincible performance and longevity. Anti-rust coated for industrial use and customized to your sizing needs, these cylindrical and linear elements are indispensable for CNC stone polishing machinery. Dont miss outadd to cart now for superior results at unmatched value.

Superior Application and Distinct Advantages

Our Stone Polishing Machinery Components seamlessly integrate with all standard CNC and manual polishing systems, ensuring optimal performance with a strict tolerance and high-precision design. The application method is mechanical, utilizing stainless steel for smooth and efficient stone finishing. Competitive advantages include lightweight design, robust anti-rust coating, and variable spindle speeds. Our components excel in polishing granite, marble, and synthetic stones, delivering consistent results across diverse application media.

Sample Policy, Payment, and Swift Delivery

We maintain stock ready for immediate supply, enabling the rapid dispatch of sample orders in secure, professional packaging. Our flexible payment terms cater to both large distributors and smaller importers, ensuring seamless transactions. Standard orders are fulfilled with prompt delivery times, meaning you experience minimal downtimes. Packaging is tailored for protection and convenience, reinforcing our commitment to hassle-free supply from Taiwans premier distributor and supplier of stone polishing machine components.

Superior Application and Distinct Advantages

Our Stone Polishing Machinery Components seamlessly integrate with all standard CNC and manual polishing systems, ensuring optimal performance with a strict tolerance and high-precision design. The application method is mechanical, utilizing stainless steel for smooth and efficient stone finishing. Competitive advantages include lightweight design, robust anti-rust coating, and variable spindle speeds. Our components excel in polishing granite, marble, and synthetic stones, delivering consistent results across diverse application media.

Sample Policy, Payment, and Swift Delivery

We maintain stock ready for immediate supply, enabling the rapid dispatch of sample orders in secure, professional packaging. Our flexible payment terms cater to both large distributors and smaller importers, ensuring seamless transactions. Standard orders are fulfilled with prompt delivery times, meaning you experience minimal downtimes. Packaging is tailored for protection and convenience, reinforcing our commitment to hassle-free supply from Taiwans premier distributor and supplier of stone polishing machine components.

FAQs of Stone Polising Machinery Components:

Q: How are these stone polishing machinery components typically used in industrial applications?

A: They are primarily designed for use within CNC and manual polishing machines to finish and process stone surfaces, delivering high-precision results with optimized efficiency.Q: What makes your stone polishing machinery components stand out from competitors?

A: Our components feature high-grade stainless steel construction, strict tolerance, anti-rust coating, and optimized cutting speeds, ensuring unbeatable durability and performance at a competitive price point.Q: When can I expect delivery upon placing an order?

A: With stock ready and efficient packaging, most orders are dispatched promptly, and delivery times are minimized based on your location and shipping method.Q: Where are these components sourced and supplied from?

A: All items are manufactured and distributed directly from Taiwan, ensuring strict adherence to industrial quality standards and reliable supply.Q: What is the process for ordering and obtaining a sample?

A: Contact us with your requirements; upon confirmation, samples are supplied from stock-ready inventory, securely packaged for swift and safe delivery.Q: What are the benefits of a high-precision and anti-rust coated component?

A: High precision ensures accurate stone polishing, while the anti-rust coating offers extended service life, reducing maintenance and operational costs for your machinery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hiwin Linear Guide Ways For Hesheng Machinery Category

Hesheng Stone Cutting Machinery Part Hiwin RGH RGW Series 25 35 45 55 65 CA-HA-Zah-Zbh

Price Range 1000.00 - 10000.00 INR

Minimum Order Quantity : 1 Piece

Machine Type : Stone Cutting Machinery

CNC : Yes

Type : CAHAZahZbh, Other

Application : Stone Cutting

Hesheng Stone Cutting Machinery Part Components

Price Range 1000.00 - 10000.00 INR

Minimum Order Quantity : 1 Piece

Machine Type : Hesheng Stone Cutting Machinery Part Components

CNC : Yes

Type : Other, Mechanical Components

Application : Stone Cutting

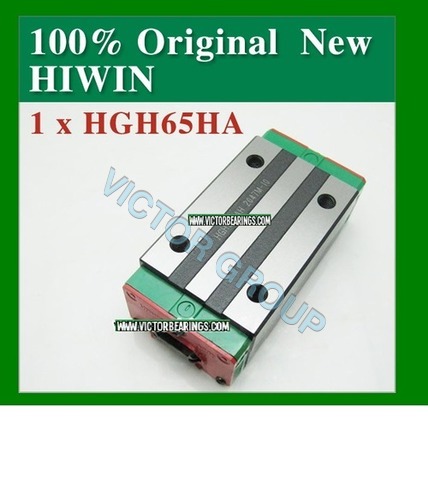

HIWIN HGH 65 HA

Price Range 1000.00 - 10000.00 INR

Minimum Order Quantity : 1 Piece

Machine Type : CNC machines and automation systems

CNC : Yes

Type : Other, Linear guide block

Application : Linear motion systems

Hesheng Stone Cutting Polising Machinery Components Hiwin Products

Price Range 1000.00 - 10000.00 INR

Minimum Order Quantity : 1 Piece

Machine Type : Stone cutting and polishing machines

CNC : Yes

Type : Other, Hiwin linear rail and bearing components

Application : Used in granite, marble, and other stone fabrication equipment

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese